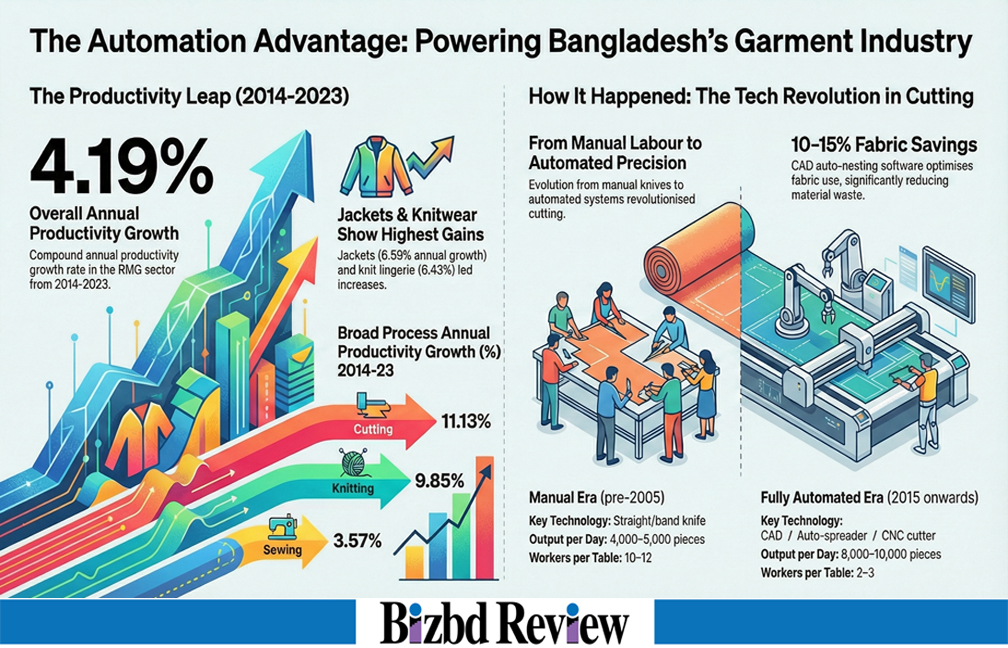

Bangladesh’s readymade garments (RMG) industry has achieved an annual productivity growth of 4.19 per cent between 2014 and 2023, driven by a move from traditional factor reliance to technology- and skill-led advancement, according to a new study by the Bangladesh Institute of Development Studies (BIDS).

The findings, presented by the BIDS research associate Kazi Zubair Hossain at the Annual BIDS Conference on Development (ABCD) on December 7.

The research focused on the RMG sector, which remains central to Bangladesh’s economy, contributing an estimated 8.5–10.5 per cent of GDP and generating 80–85 per cent of export earnings.

The primary motivation for the study was the limited understanding of technological change within the country’s manufacturing base, where policy and discourse have tended to prioritise labour upskilling while overlooking the critical role of technology in driving productivity.

The analysis sought to quantify technological changes over the past decade at a granular sub-process level, a methodological approach considered essential for identifying shifts in unique production functions and informing targeted policymaking.

The results showed uneven progress across product categories and processes, with firms producing jackets recording the highest annual productivity growth at 6.59 per cent, followed closely by knit-lingerie at 6.43 per cent and sweaters at 6.05 per cent.

More traditional woven products saw considerably slower gains, with woven shirts at 3.00 per cent, denim at 1.81 per cent, and woven trousers at just 1.15 per cent.

When processes were recategorised, the contrast became even clearer: automation-intensive areas drove the strongest performance, with cutting achieving an annual productivity increase of 11.13 per cent, knitting 9.85 per cent, and wet processing 6.11 per cent.

Sewing, which remains the least automated and most labour-dependent component of the production chain, posted the lowest growth at 3.57 per cent.

To address the broader knowledge gap, the research examined three interconnected issues: identifying and quantifying technological changes in the RMG industry at the sub-process level across eight key product types, and exploring whether technological convergence is taking place across firms and tasks.

The study was based on a purposive survey of 51 export-oriented RMG factories—excluding smaller firms—carried out between June and December 2024.

It combined qualitative methods such as key informant interviews, focus group discussions, and in-depth interviews with quantitative data collected through structured questionnaires.